Name: Mr.Hu胡先生

Tel: 15868229433

Fax: 0086-577-85989655

E-mail: patrick@cnjdgy.com

QQ: 1079338461

Add: No 111 , Longwan District ,Wenzhou,China

|

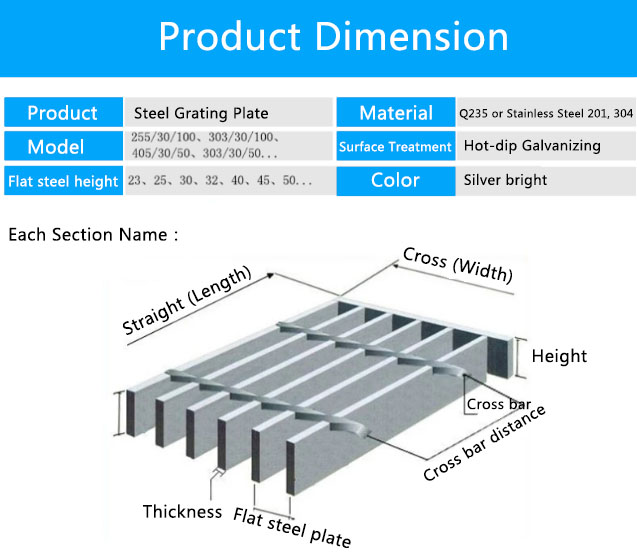

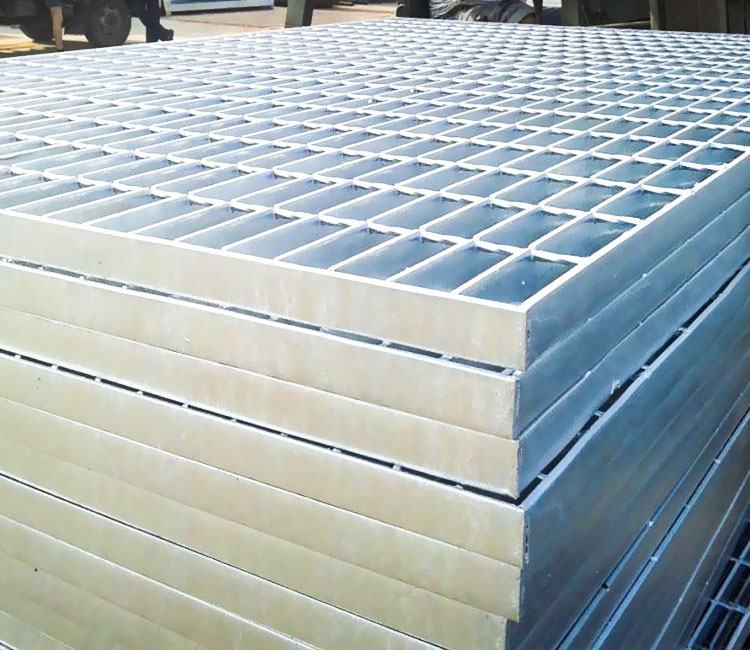

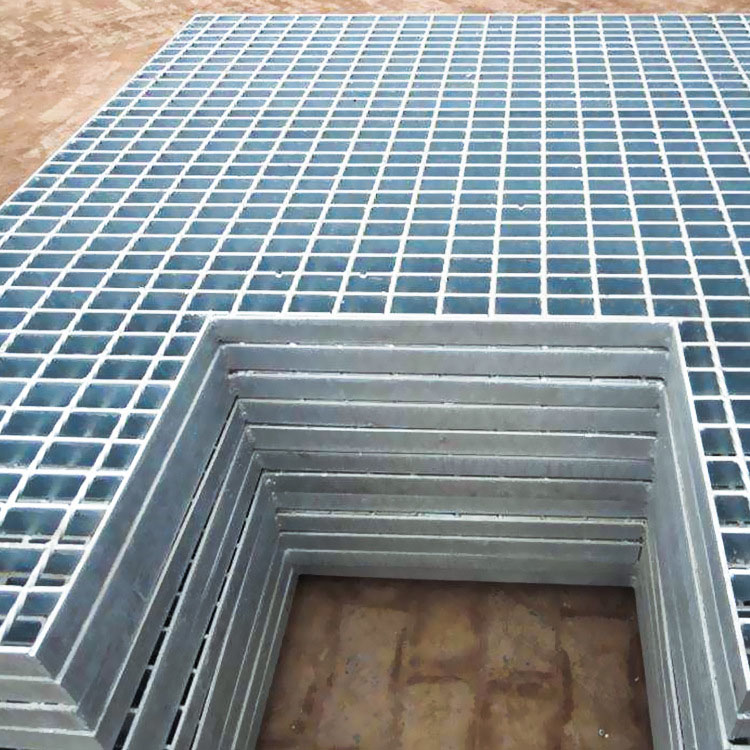

Hot-dip galvanized steel grating

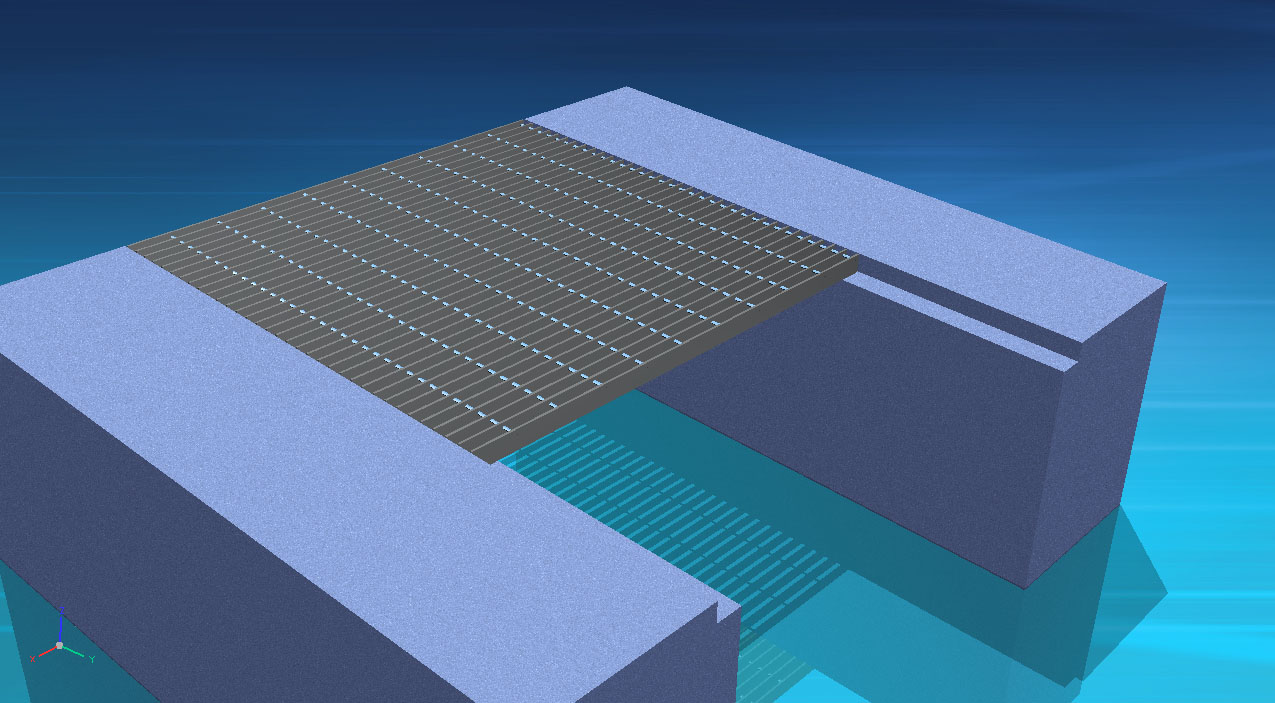

information: Hot-dip galvanized steel grating, also known as hot-dip galvanized steel grating, is a grid-shaped building material made of low-carbon steel flat steel and twisted square steel welded horizontally and vertically. Hot-dip galvanized steel grating has strong impact resistance, strong corrosion resistance and heavy load capacity, elegant and beautiful, and has excellent performance in municipal roadbed and steel platform construction projects. The extremely high cost performance is that hot-dip galvanized steel gratings are widely used in the construction of new and old roadbeds to cover water channel roads.

|

The surface of the hot-dip galvanized steel grating plate is subjected to special hot-dip galvanizing treatment, and its chemical and physical properties are stable, and it is not easily corroded by air and microorganisms. It can significantly enhance the load of the trench. Prevent collapse. The hot-dip galvanized steel grating plate with a flat steel spacing of 3 cm has a large impact resistance and the largest span amplitude. It has long service life, it is general usage lifespan around 40 years to 50 years’s. If no man-made destruction factor, the hot-dip galvanized steel grating plate is a very good steel frame structure and load-bearing platform.

1. The characteristics of hot-dip galvanized steel grating plate are: high strength, light structure: firm grid welding structure makes it have high load-bearing, light structure, easy to hoist and so on; beautiful appearance and durable.

2. Hot-dip galvanized steel grating plate application: widely used in petrochemical, power plants, water plants, sewage treatment plants, municipal engineering, sanitation engineering and other fields of platforms, walkways, trestles, trench covers, manhole covers, ladders, fences, guardrails, etc.

Production Process

1. Preparing Raw Material

The steel grating is generally made of 40mm wide and 3mm thick Q235B flat steel with a spacing of 30mm. The crossbar spacing is 50mm. Can be customized according to customer needs.

2.Welding Steel Grating Plate

(1)The welding of the steel grating plate is mechanical pressure welding, and the machine pressure welding uses a high-voltage electric resistance welding machine. The robot automatically traverses the crossbar on the evenly arranged flat steel, and presses the crossbar into the flat by strong welding power and hydraulic pressure. Inside the steel, a steel grating with firm solder joints, high stability and strength is obtained.

(2)Manual welding requires first punching on the flat steel, then placing the crossbar into the hole for electric welding. There is a gap between the crossbar and the flat steel, and it cannot be welded at every point. Therefore, the welding is not strong and the strength is not as good as that of the machine. welding.

3.Cutting

According to the size required by the customer, the entire steel grating plate after welding must also be mechanically cut. (Refer to Introduction of high-efficiency energy-saving steel grating plate shearing machine) Strictly control the dimensional precision error when cutting. After the cutting is completed, the professional quality inspectors will sample the cut steel grating and the unqualified steel grating will be re-cut.

4.End plate (Edge Covering Plate) Welding

The end plate is the same as the flat steel material in the steel grating, and is welded by manual welding. Welding can be carried out after removing the oil stains and stains on the surface of the steel grating during welding. The weld is a single-face fillet weld. Each flat steel of the steel grating needs to be welded to the end plates. After the welding is completed, the surface is slag removed and smoothed.

5.Hot-dip Galvanizing

Hot-dip galvanizing is an essential process for steel gratings. Before galvanizing, you should choose blasting or blasting out the surface rust, so that there are no oil, rust and other dirt on the surface. The average zinc layer weight after galvanizing is not less than 460 g/m2, and the quality after galvanizing should be complying the requirements of GB/T13912.

Characteristics

Material saving and cost reduction:The way to bear the most material under the same load conditions, correspondingly, can reduce the material of the supporting structure, save materials, save labor, save labor, and avoid cleaning and maintenance.

The construction is simple and the construction period is saved: the pre-installed support is fixed by bolt clamp or welded, and can be completed by one person. The product does not need to be reworked on site, and the installation is very rapid.

Anti-soil, modern style: no accumulation of rain, snow and dust. Beautiful appearance, design specifications, ventilation and light, giving people a modern and smooth feeling.

Reducing wind resistance and durability: Because of good ventilation, it is less windy and wind-damaged. It is treated with hot-dip galvanizing and anti-corrosion treatment before leaving the factory, which has strong impact resistance and heavy pressure.

Lightweight structure and simple design: no need for small beams, simple structure, simplified design; no need to design steel grating details, only the model number can be, the factory can design the layout chart on behalf of customers. The material is small, the structure is light, and it is easy to hoist.

Ventilation,lighting, heat dissipation, explosion-proof, good anti-slip performance: acid-base corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

Ventilation,lighting, heat dissipation, explosion-proof, good anti-slip performance: acid-base corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

|

|

|

|

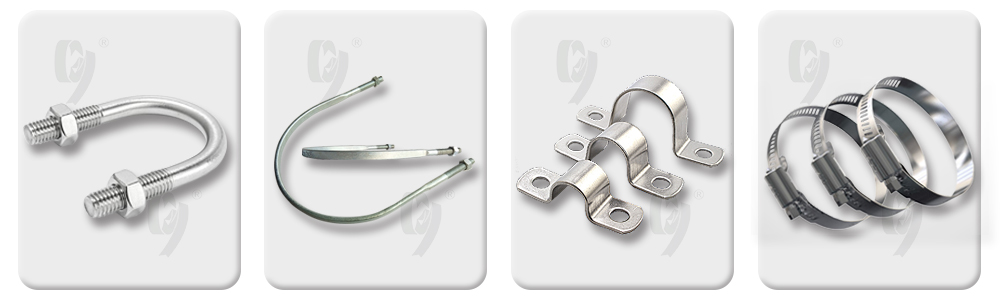

Stainless Steel Pipes & Tubes

Stainless Steel Pipes & Tubes